Good News

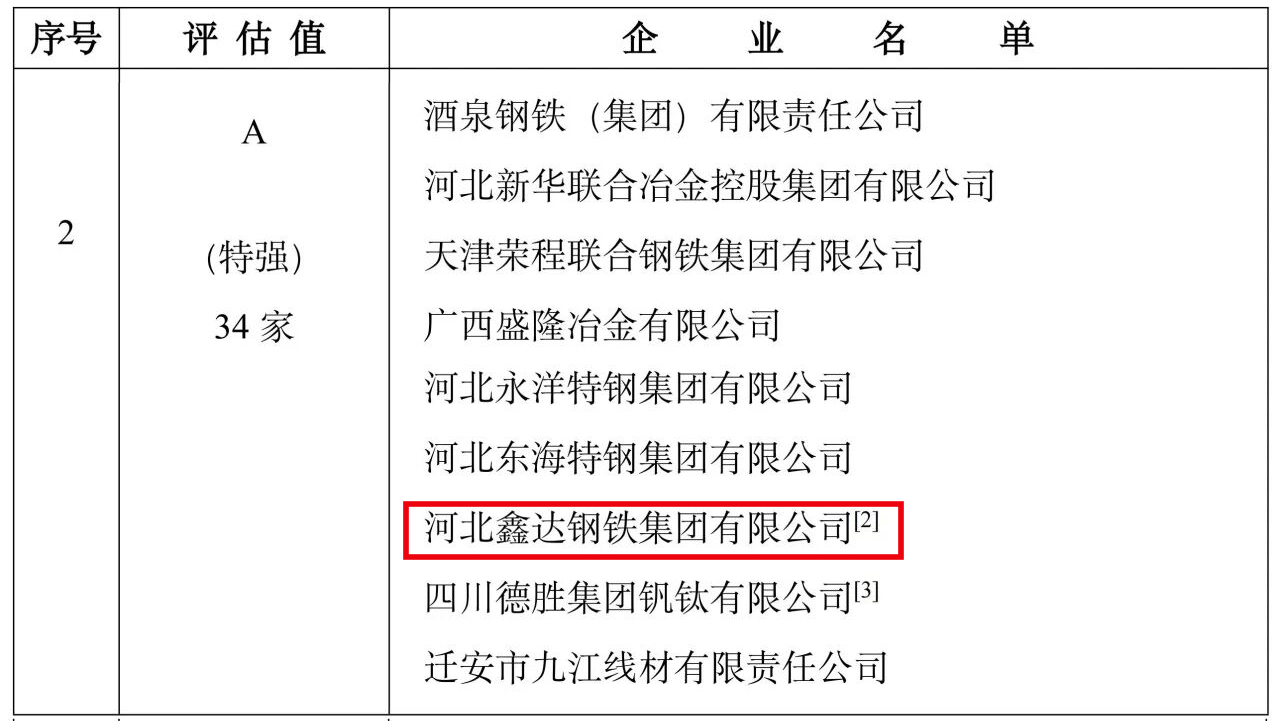

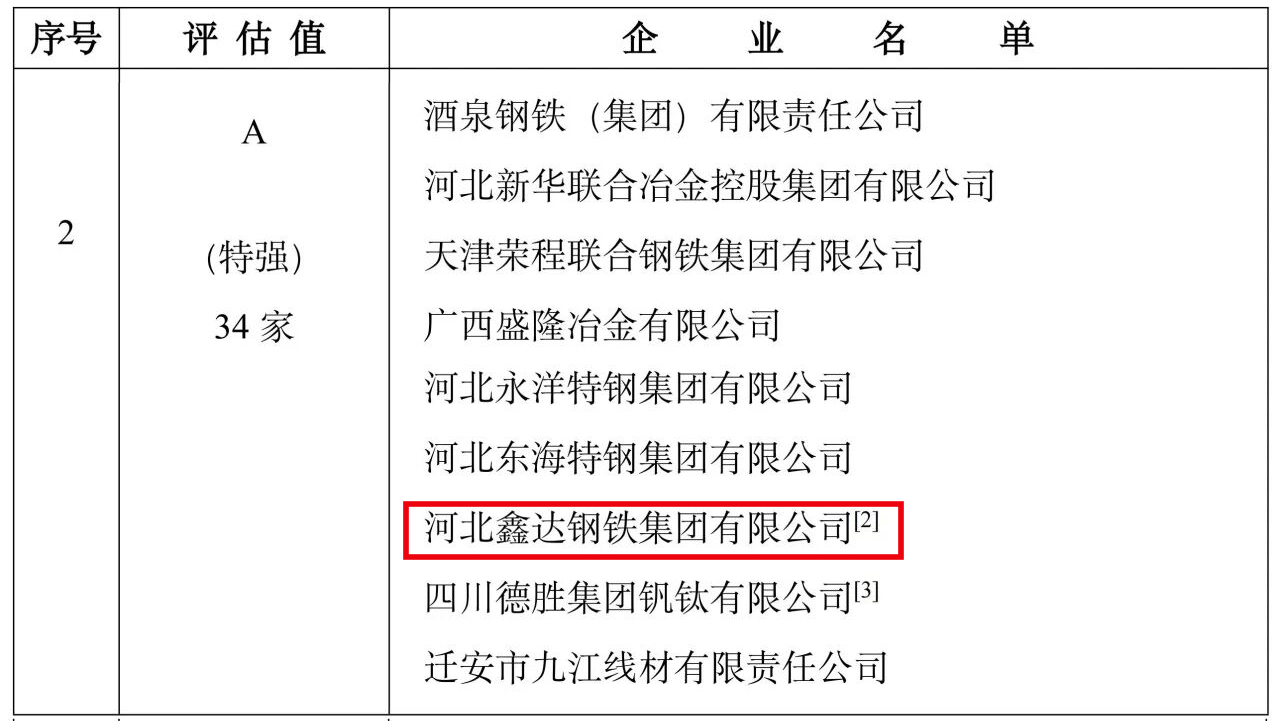

Recently, the Metallurgical Industry Planning and Research Institute released the "Research Results on the Competitiveness (and Development Quality) Rating of Domestic Steel Enterprises in 2025". Hebei Xinda Steel Group Co., Ltd. was successfully rated as a "2025 China Steel Enterprise Competitiveness A-level (Extra Strong) Enterprise" due to its outstanding performance in production and manufacturing, technological research and development, green and low-carbon development, and refined management. This achievement fully demonstrates the company's solid strength and industry status in the high-quality development process of the steel industry.

It is understood that the Metallurgical Industry Planning and Research Institute has been conducting research and releasing the competitiveness (and development quality) rating of domestic steel enterprises for 15 consecutive years. This year's rating of domestic steel enterprises' competitiveness (and development quality) is divided into four major sections, 16 elements, and 32 indicators, establishing a standard indicator system framework. A total of 109 enterprises were included in this assessment, with a combined crude steel output of 930 million tons, accounting for 92.6% of the national total output.

Precision Craftsmanship Builds Quality Products, Solid Empowerment Enhances Competitiveness

Xinda has set its strategic direction towards high-end products and diversified categories, establishing a product matrix that includes high-quality hot-rolled ribbed steel bars, hot-rolled premium strip steel, hot-rolled high-quality H-beams, and hot-rolled coil plates. It has established R&D platforms such as the National CNAS-recognized Quality Inspection Center and the Hebei Provincial Enterprise Technology Center, continuously promoting the optimization of product structure and the upgrading of quality levels. Its series of products have obtained the National Industrial Product Production License, ISO9001 system certification, Korean KS certification, and National Metallurgical Product MC certification. It has been designated as a specified steel bar producer for the Xiongan New Area and awarded the "Golden Cup Quality Product" by the China Iron and Steel Association, and has won the "Mayor's Quality Award of Qian'an City".

From the national key project, Yangjiang Nuclear Power Station, to the modern urban benchmark, Shenzhen Bay Super Headquarters Base; from the national railway arteries running north and south, such as the Jinxiang High-Speed Railway and the Xi-Chongqing High-Speed Railway, to the over 40 key projects in full swing in Xiongan New Area, the presence of Xinda's products can be found everywhere, contributing to the construction of the country's grand edifice with the power of steel. Meanwhile, its overseas territory continues to expand, with products sold to 27 countries and regions including Singapore, Indonesia, and Malaysia. Its export performance has been climbing year after year, injecting vigorous momentum into the construction of a steel power.

Innovate for the Future, Enhance Efficiency and Quality

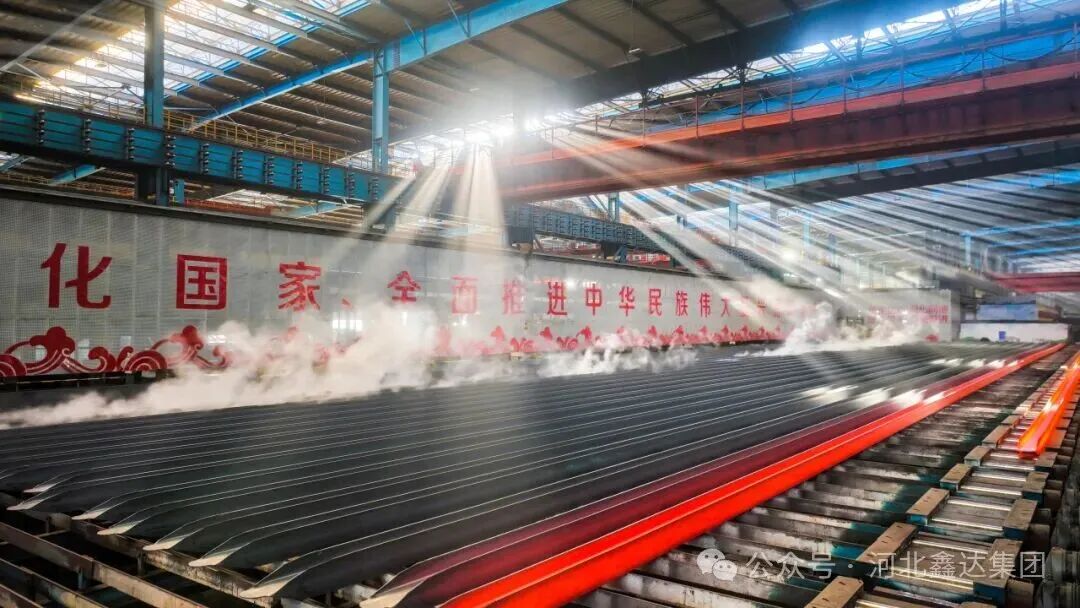

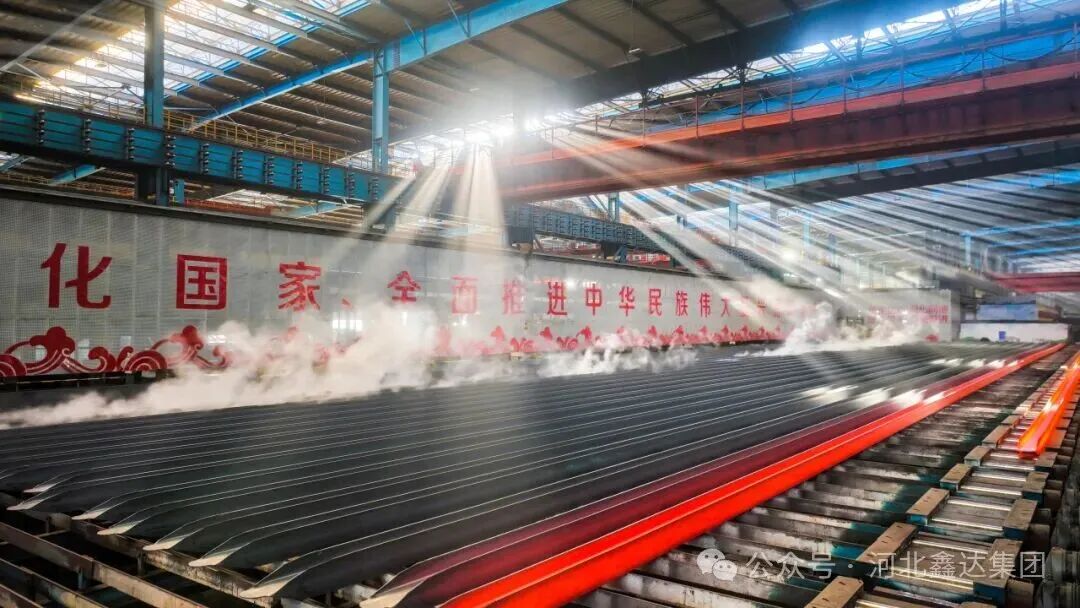

In the era of intelligent manufacturing, Xinda dares to be the first. Its industrial ring network and 5G private network are seamlessly integrated, building an "8+2+1" intelligent manufacturing system. This system enables full-process data interconnection and business collaboration, completely breaking down data silos and business barriers, and achieving a qualitative leap in production efficiency and operational effectiveness. In the workshop, 14 intelligent mechanical arms operate precisely, and over 10 sets of intelligent automation systems run smoothly. The unmanned continuous casting platform applies two robots to simultaneously replace the long water mouth, setting a global precedent in the industry. This showcases Xinda's strong strength in the field of intelligent manufacturing.

In the ironmaking process, the intelligent optimization combustion system of the hot blast stove acts like a smart brain. By precisely predicting key parameters such as the top temperature and residual oxygen in the exhaust gas, it enables the reinforcement learning agent to dynamically adjust the opening degrees of the gas and air valves, achieving closed-loop optimization control. This not only reduces gas consumption by more than 3%, significantly reduces manual intervention, but also significantly improves energy utilization efficiency, saving over 5 million yuan annually. In the steel rolling process, the intelligent optimization combustion system of the heating furnace replaces the traditional experience-based operation mode. By fully automatically optimizing the air-fuel ratio and furnace temperature distribution, it makes the smelting process more stable and energy consumption more controllable, achieving a reduction in gas consumption of more than 3% and a decrease in oxidation loss of 0.05%. The annual cost reduction exceeds 10 million yuan, injecting strong impetus into the high-quality development of the enterprise.

Green transformation and ecological symbiosis

Xinda actively responds to the national strategy of green and low-carbon development. With a strong sense of responsibility and mission, it has been deeply engaged in the path of green transformation and has become the first steel enterprise in Hebei Province to pass the re-evaluation of environmental performance A-level enterprises. It interprets the ecological responsibility of steel enterprises with practical actions. It conducts in-depth environmental governance and transformation throughout the entire production process, and has an integrated air pollution prevention and control technology system covering the entire steel production process, including source reduction, process control and end treatment, making green development run through the entire production and operation.

In terms of environmental protection facility construction, advanced environmental protection technologies and equipment have been introduced. All material storage areas have been built into fully enclosed mechanized material sheds. Key dust-generating points are equipped with ventilation and dust collection systems as well as intelligent dry fog dust suppression systems, achieving the ultra-low emission standards throughout the entire process. A comprehensive ultra-low emission control, management and treatment integrated platform for the entire factory has been established, enabling intelligent monitoring of environmental protection facilities, automatic early warning and push notifications of environmental protection data, precise control of unorganized sources, and real-time dispatching of clean transportation. Today, Xinda is a place with lush green trees and fresh air, contributing valuable experience and solid strength to the sustainable development of the steel industry.

Conclusion

Great achievements stem from hard work, and brilliance is forged through struggle. XinDa's attainment of the A-level (Extra Strong) rating is a dual endorsement of its strength and vision. In the future, Hebei XinDa Steel Group Co., Ltd. will take intelligence as the core, unlock the potential of data, enabling machines to think and factories to be smart; take green development as the pulse, integrating it throughout the production process, allowing steel to coexist harmoniously with nature; and focus on precision, concentrating on the R&D field to create irreplaceable high-quality products. It will integrate resources with a broader perspective and secure the future with a more advanced layout, building a new high ground in the steel industry characterized by independent and controllable technology and a widely acclaimed brand. With greater strength, more outstanding performance, and deeper commitment, XinDa will stride forward on the journey of transformation and upgrading, take the initiative to shoulder responsibilities in serving national strategies and promoting economic development, contribute more and stronger XinDa power to the manufacturing power of the country, and shine with even more brilliant luster!

Email

Email Email

Email